SolidWorks Knowledge Base: Forget frantic Googling! This isn’t your grandpa’s CAD manual. We’re diving deep into the treasure trove of tutorials, FAQs, and troubleshooting tips that’ll turn you into a SolidWorks ninja. Get ready to unlock the secrets to conquering even the trickiest design challenges – from mastering complex surfaces to troubleshooting those pesky error messages. Think of it as your personal SolidWorks sensei, always ready with the answers.

This guide will walk you through everything from efficiently searching the SolidWorks Knowledge Base to understanding its structure and utilizing its various resources, including API documentation and community forums. We’ll also explore the quality of its content, compare it to competitors, and discuss future trends in SolidWorks support. Get ready to level up your SolidWorks game!

SolidWorks Knowledge Base Structure

The SolidWorks knowledge base serves as a crucial resource for users of all skill levels, providing access to a comprehensive collection of information vital for efficient software utilization and problem-solving. A well-structured knowledge base is essential for maximizing user productivity and minimizing troubleshooting time. This analysis examines the structure of the SolidWorks knowledge base, comparing it to other CAD software knowledge bases and proposing improvements for optimal user experience.

Comparison of CAD Software Knowledge Bases

The effectiveness of a CAD software knowledge base hinges on several key factors: accessibility, search functionality, and content quality. The following table compares SolidWorks to other prominent CAD software packages based on these criteria. Note that these assessments are based on general observations and may vary depending on specific versions and updates of the software.

| Software Name | Knowledge Base Accessibility | Search Functionality | Content Quality |

|---|---|---|---|

| SolidWorks | Generally accessible, requiring user registration. Multiple access points may exist (website, in-software help). | Offers robust search with filtering options; however, the effectiveness can vary depending on search terms. | High-quality content including tutorials, FAQs, and troubleshooting guides; however, the consistency of information across different content types may vary. |

| Autodesk AutoCAD | Readily accessible online, often integrated directly within the software. | Provides comprehensive search functionality with auto-suggestions and related content. | Wide range of content, but quality can vary across different sections and contributors. |

| PTC Creo | Accessible through the PTC website and integrated within the software. | Search functionality is generally effective, but advanced search options may be limited. | Good quality content, but the depth of coverage for certain topics may vary. |

| Siemens NX | Accessibility varies depending on licensing and support agreements. | Search functionality is generally reliable, with options for filtering by category. | High-quality content is available but may require a subscription or specific support contract. |

Types of Content within the SolidWorks Knowledge Base

The SolidWorks knowledge base encompasses a diverse range of content designed to address the varying needs of its users. This includes detailed tutorials guiding users through specific workflows, frequently asked questions (FAQs) addressing common issues, troubleshooting guides providing step-by-step solutions to known problems, and comprehensive documentation outlining the software’s features and functionalities. Additionally, the knowledge base often includes videos, images, and interactive elements to enhance user understanding.

Ideal Navigation Structure for a SolidWorks Knowledge Base

A well-designed navigation structure is critical for efficient knowledge base usage. The following points Artikel an ideal structure prioritizing user experience.

Prioritizing intuitive navigation and efficient information retrieval is paramount for a successful knowledge base. A clear, hierarchical structure ensures users can quickly locate the information they need, regardless of their technical expertise.

- Clear Categorization: Organize content into logical categories (e.g., Modeling, Simulation, Drawings, Assemblies). Subcategories should be used to further refine the organization.

- Search Functionality Enhancement: Implement advanced search options, including filters for content type (tutorial, FAQ, etc.), software version, and s.

- Intuitive Search Results: Present search results in a clear and concise manner, with relevant metadata (e.g., date, content type, rating) displayed prominently.

- Contextual Help: Integrate contextual help directly within the SolidWorks software, allowing users to access relevant information based on their current task.

- User Feedback Mechanisms: Include mechanisms for users to rate content, provide feedback, and report errors or omissions.

- Version Control: Clearly indicate the SolidWorks version to which the content applies.

- Regular Updates: Maintain the knowledge base with frequent updates to reflect new features, bug fixes, and best practices.

Accessing and Utilizing SolidWorks Help Resources

Effective utilization of SolidWorks’ help resources is crucial for maximizing productivity and problem-solving efficiency. The integrated help system and online knowledge base provide comprehensive support, ranging from basic tutorials to advanced troubleshooting guides. Mastering these resources significantly reduces the time spent on resolving design challenges and accelerates the overall design process.

Efficient navigation and effective search strategies are paramount for quickly locating relevant information within the extensive SolidWorks help system. The following sections detail methods for accessing and utilizing these resources effectively.

Accessing SolidWorks Help Resources

SolidWorks offers multiple avenues for accessing its comprehensive help resources. The primary methods include in-software help, accessible directly within the SolidWorks application, and the online SolidWorks knowledge base, a web-based portal containing a vast collection of articles, tutorials, and troubleshooting guides. Additionally, third-party resources such as online forums and communities provide supplemental support and collaborative problem-solving opportunities.

Efficient Search Strategies within the SolidWorks Knowledge Base

Locating specific solutions within the SolidWorks knowledge base requires employing effective search strategies. Begin by using precise s related to the specific problem encountered. For instance, instead of searching for “problem with assembly,” a more effective query might be “SolidWorks assembly constraint error message.” Using specific error messages or feature names significantly improves search accuracy. Experiment with different combinations and phrasing to refine search results.

Utilize Boolean operators such as “AND,” “OR,” and “NOT” to further refine searches. For example, searching for “SolidWorks part file AND import AND STEP” will yield results specifically related to importing STEP files into SolidWorks part documents.

Examples of Effective Search Queries

The following examples illustrate effective search queries for common SolidWorks problems:

- Problem: Unable to create a revolved feature. Effective Search Query: “SolidWorks revolved feature error” or “SolidWorks revolved feature failed to create”.

- Problem: Difficulty understanding the use of a specific SolidWorks command. Effective Search Query: “SolidWorks [command name] tutorial” or “SolidWorks [command name] explanation”. Replace “[command name]” with the actual command, for example, “SolidWorks Pattern Feature tutorial”.

- Problem: Encountering a specific error message. Effective Search Query: Enter the exact error message verbatim. SolidWorks’ search function is often highly effective at matching exact error message text.

Step-by-Step Guide to Searching for Solutions

- Identify the problem: Clearly define the issue you are facing. Note specific error messages, symptoms, and relevant context.

- Formulate a search query: Construct a concise and precise search query using relevant s. Include specific error messages, feature names, or commands.

- Access the SolidWorks knowledge base: Access the knowledge base through the in-software help menu or the online portal.

- Refine your search: If initial results are unsatisfactory, refine your search query by adding more specific s or using Boolean operators.

- Review the results: Carefully review the search results. Select the most relevant articles or tutorials based on their titles and descriptions.

- Implement the solution: Follow the instructions provided in the selected article or tutorial to resolve the issue.

SolidWorks Knowledge Base Content Quality

The SolidWorks knowledge base serves as a crucial resource for users seeking assistance with the software. However, its effectiveness is contingent upon the clarity, organization, and comprehensiveness of its content. Areas requiring improvement can significantly enhance user experience and problem-solving capabilities.Areas Requiring Improvement in Clarity and Organization within the SolidWorks Knowledge Base involve inconsistent terminology, scattered information across multiple pages for related topics, and a lack of visual aids in certain complex procedures.

The search functionality could also benefit from enhanced algorithms to deliver more precise results, reducing the time users spend sifting through irrelevant information. Furthermore, a more intuitive categorization system would improve navigation and access to relevant help articles. Improved cross-referencing between related articles would also strengthen the overall usability of the knowledge base.

Comparison of SolidWorks Knowledge Base with Competitor Offerings

The following table compares the SolidWorks knowledge base to a hypothetical competitor (Competitor A) across several key features. Note that “Competitor A” represents a generalized competitor and specific features may vary depending on the actual competitor chosen. This comparison is for illustrative purposes only and does not constitute a comprehensive evaluation of all competitors.

| Feature | SolidWorks | Competitor A |

|---|---|---|

| Search Functionality | Generally effective, but can sometimes return irrelevant results. Requires refinement of search algorithms. | Offers advanced search filters and natural language processing, leading to more precise results. |

| Content Organization | Information is organized by software version and topic, but can be improved with more intuitive categorization and cross-referencing. | Employs a hierarchical structure with clear topic categorization and extensive cross-linking between related articles. |

| Visual Aids | Uses screenshots and videos effectively in many areas, but could benefit from more visual aids in complex procedures. | Provides a greater emphasis on visual aids, including interactive tutorials and 3D models, to enhance understanding. |

| Community Support Integration | Limited integration with community forums. | Seamlessly integrates with a robust online community forum, allowing users to access peer support and solutions. |

Solving a Specific Design Challenge Using the SolidWorks Knowledge Base

Consider the challenge of creating a complex curved surface using SolidWorks. A user unfamiliar with the advanced surfacing tools might struggle. By utilizing the knowledge base, the user can search for terms like “creating curved surfaces,” “sweep features,” or “ruled surfaces.” The search results would likely include articles detailing the different methods available, along with step-by-step instructions and visual aids demonstrating each technique.

For instance, an article might explain the parameters involved in creating a sweep feature, including the profile curve, path curve, and the options for controlling the twist and scale of the resulting surface. By carefully reviewing these articles and experimenting with the different options, the user can effectively create the desired curved surface. The knowledge base, in this scenario, acts as a structured learning resource, enabling users to acquire new skills and solve complex design problems.

SolidWorks API Documentation within the Knowledge Base

Comprehensive API documentation is crucial for advanced SolidWorks users seeking to extend the software’s capabilities beyond its standard functionalities. Access to well-structured and detailed API documentation empowers users to develop custom add-ins, automate repetitive tasks, and integrate SolidWorks with other applications, significantly enhancing productivity and workflow efficiency. This documentation serves as the foundational resource for leveraging the power of SolidWorks’ programmable interface.The SolidWorks API documentation provides a detailed description of the objects, methods, and properties that constitute the SolidWorks API.

This allows developers to interact programmatically with SolidWorks models, features, and environments. Effective utilization of this documentation is essential for successful add-in development.

SolidWorks API Documentation Structure

The SolidWorks API documentation is organized hierarchically to facilitate navigation and understanding. The structure is designed to be intuitive, guiding users from general concepts to specific implementation details. A logical understanding of this structure is critical for efficient use of the API.

- Overview: Provides a general introduction to the SolidWorks API, its capabilities, and its purpose. This section often includes information on the programming languages supported (typically VBA, C#, and C++) and the necessary development environment setup.

- Object Model: Details the hierarchical structure of the SolidWorks API objects. This section is typically represented visually through diagrams or charts, showing the relationships between different objects and their properties. Understanding this model is paramount for navigating the API and identifying the appropriate objects to interact with.

- Object Reference: This section contains detailed descriptions of each individual object within the API. Each object description includes a list of its properties, methods, and events. Properties describe the characteristics of the object, methods define the actions that can be performed on the object, and events signal changes in the object’s state.

- Examples and Tutorials: The documentation typically includes numerous code examples and tutorials demonstrating how to use various API functions. These examples are essential for learning by doing and understanding how different API elements work together in practical applications. They often cover common tasks, such as creating features, manipulating models, and interacting with the SolidWorks user interface.

- Reference Materials: This section may include links to external resources, such as programming language documentation or relevant SolidWorks support articles. These resources provide additional context and support for specific coding challenges.

Creating a Custom SolidWorks Add-in Using API Documentation

Developing a custom SolidWorks add-in involves several key steps, all guided by the API documentation. The process requires a strong understanding of the API object model and the ability to write code in a supported programming language.

- Identify Required Functionality: Clearly define the specific tasks the add-in should perform. This step is crucial for selecting the appropriate API objects and methods to use.

- Object Selection: Using the API object model and object reference sections of the documentation, identify the relevant objects and their properties and methods to achieve the desired functionality. This involves careful analysis of the relationships between different objects and how they interact.

- Code Development: Write the code in a supported language (e.g., VBA, C#, C++) using the information obtained from the API documentation. This includes instantiating objects, setting properties, calling methods, and handling events.

- Error Handling: Implement robust error handling mechanisms to catch and address potential issues during the add-in’s execution. The API documentation often provides information on common error codes and how to handle them.

- Testing and Debugging: Thoroughly test the add-in to ensure it functions correctly and meets the defined requirements. Use the SolidWorks debugging tools to identify and resolve any issues.

- Deployment: Package and deploy the add-in for use within SolidWorks. This typically involves creating an add-in file (.dll or .exe) and installing it in the appropriate SolidWorks directory.

For example, to create a simple add-in that creates a new part file and adds a cube feature, one would consult the documentation to find the relevant objects (e.g.,

PartDoc,FeatureManager,ExtrudeFeature) and their methods (e.g.,CreateExtrude). The code would then instantiate these objects, set the necessary parameters, and call the appropriate methods to achieve the desired outcome.

Troubleshooting Using the SolidWorks Knowledge Base

The SolidWorks Knowledge Base serves as a valuable resource for resolving various software-related issues. Effective utilization of this resource significantly reduces troubleshooting time and enhances productivity. This section details strategies for leveraging the knowledge base to diagnose and resolve SolidWorks errors.

Step-by-Step Troubleshooting of “Failed to load part: [PartName].sldprt – Error code: 12345”

This guide Artikels the process of using the SolidWorks Knowledge Base to address the error “Failed to load part: [PartName].sldprt – Error code: 12345”. The steps are designed to provide a structured approach to problem-solving.

- Accessing the SolidWorks Knowledge Base: Navigate to the SolidWorks website and locate the support or knowledge base section. [Screenshot of SolidWorks website support page would be inserted here showing the navigation path].

- Entering the Error Message: In the search bar, enter the complete error message: “Failed to load part: [PartName].sldprt – Error code: 12345”. [Screenshot of the search bar with the error message entered would be inserted here].

- Reviewing Search Results: Examine the search results for relevant articles. Prioritize articles that specifically mention the error code “12345” and the file extension “.sldprt”. [Screenshot of search results page showing relevant articles would be inserted here].

- Reading the Relevant Article: Open the most relevant article and carefully review the troubleshooting steps and potential solutions. [Screenshot of a knowledge base article page with relevant troubleshooting steps highlighted would be inserted here].

- Implementing Solutions: Attempt the suggested solutions from the knowledge base article. This may involve checking file permissions, repairing the file, or reinstalling SolidWorks. Document each step taken and the results.

- Escalating the Issue: If the problem persists after trying all the solutions in the knowledge base article, contact SolidWorks support for further assistance.

Examples of Common SolidWorks Assembly Errors and Solutions

This section provides three common SolidWorks assembly errors, their corresponding solutions, and links to relevant knowledge base articles (replace with actual links if available).

| Error | Solution | Knowledge Base Article Link (Placeholder) |

|---|---|---|

| Mate constraint failure: “Cannot create mate” | Verify component geometry compatibility, check for conflicting constraints. | [Link to relevant KB article] |

| Component placement error: “Component cannot be placed” | Check for interference, ensure correct coordinate system, review component origin. | [Link to relevant KB article] |

| Interference detection error: “Interference detected” | Utilize SolidWorks’ interference detection tools, adjust component positions, modify geometry. | [Link to relevant KB article] |

Troubleshooting Process Flowchart

A flowchart visually represents the decision-making process when troubleshooting with the SolidWorks Knowledge Base.[A flowchart would be inserted here. The flowchart would begin with “Error Encountered,” branch to “Is the error message clear?”, then branch to “Search SolidWorks Knowledge Base,” followed by “Did the knowledge base article resolve the issue?” Yes would lead to “Issue Resolved,” No would lead to “Try alternative solutions/contact support”.

Another branch from “Is the error message clear?” would lead to “Clarify the error message” and then back to “Search SolidWorks Knowledge Base”. Another branch from “Search SolidWorks Knowledge Base” would lead to “No relevant articles found” and then to “Try alternative solutions/contact support”.]

SolidWorks Error Categories and Examples

This table categorizes common SolidWorks errors and provides examples within each category.

| Error Category | Error Message Example 1 | Error Message Example 2 |

|---|---|---|

| File Corruption | “File is corrupted and cannot be opened” | “Error reading file: [filename]” |

| Memory Issues | “Out of memory” | “SolidWorks has encountered a problem and needs to close” |

| Add-in Conflicts | “Add-in failed to load” | “Error initializing add-in: [add-in name]” |

| Graphics Card Problems | “Graphics card driver error” | “SolidWorks is running slowly or crashing” |

| Licensing Issues | “Invalid license” | “License server not found” |

Programmatic Access to the SolidWorks Knowledge Base

Direct programmatic access to the SolidWorks Knowledge Base is generally not available through a public API. Web scraping techniques could potentially be used, but this is highly discouraged due to the potential for breaking terms of service and the inherent instability of relying on the structure of a website’s HTML.

Limitations of the SolidWorks Knowledge Base and Alternative Methods

The SolidWorks Knowledge Base may not contain solutions for all errors, particularly those caused by unique hardware configurations or specific workflow issues. Alternative troubleshooting methods include: searching online forums, consulting with SolidWorks experts or experienced users, reinstalling SolidWorks, and contacting SolidWorks technical support.

Effective Usage for Knowledge Base Searches

Effective selection is crucial for efficient knowledge base searches. Use specific error messages, component names, and relevant SolidWorks features as s. Employ Boolean operators such as AND, OR, and NOT to refine your search and exclude irrelevant results. For example, searching for “assembly AND constraint AND error 123” will yield more precise results than a general search for “assembly error.”

Comparison of Search and Browsing Methods

The SolidWorks Knowledge Base’s search function is most effective when a specific error message or a clear description of the problem is available. Browsing the categorized articles is more beneficial when the user has a general understanding of the problem area but lacks a specific error message. For example, searching is ideal for error code resolution, while browsing is useful for learning about specific SolidWorks features or functionalities.

SolidWorks Training Materials within the Knowledge Base

The SolidWorks knowledge base offers a range of training materials intended to supplement formal instruction and provide users with ongoing support. The effectiveness of these materials, however, varies depending on the user’s prior experience and learning style. While providing a valuable resource, they often lack the personalized instruction and interactive feedback found in professional training courses.The SolidWorks knowledge base’s training resources primarily consist of documentation, video tutorials, and example projects.

These materials aim to cover a wide range of topics, from fundamental interface navigation to advanced modeling techniques and simulation workflows. The effectiveness of this approach hinges on the clarity of the materials, the logical progression of lessons, and the availability of supplementary resources to address specific challenges encountered by users.

Comparison of SolidWorks and Third-Party Training Materials

SolidWorks’ in-house training materials provide a foundational understanding of the software. They are generally free and readily accessible, making them a cost-effective option for initial learning or for addressing specific software features. However, third-party training providers often offer more structured curricula, personalized instruction, hands-on exercises, and certification opportunities. These providers can tailor their courses to specific industry needs and skill levels, resulting in a potentially more efficient and effective learning experience, although at a significant cost.

For example, a third-party course might offer focused training on advanced FEA techniques, whereas the SolidWorks knowledge base might only provide introductory information on the topic, dispersed across multiple documentation pages.

Categorization of SolidWorks Training Materials

The following table categorizes the types of training materials available within the SolidWorks knowledge base:

| Category | Description | Effectiveness |

|---|---|---|

| Video Tutorials | Short videos demonstrating specific features or workflows. | Generally effective for visual learners, but may lack depth for complex topics. |

| Written Guides | Step-by-step instructions and explanations of various features. | Useful for detailed understanding but may be less engaging for some learners. |

| Example Projects | Pre-built models and assemblies that illustrate specific techniques. | Effective for practical application but require a degree of prior knowledge. |

| Interactive Exercises (limited) | Some tutorials include interactive elements, but these are generally limited in scope. | While beneficial when available, the limited extent hinders comprehensive skill development. |

Community Forums and Support within the SolidWorks Ecosystem

The SolidWorks ecosystem extends beyond its official knowledge base, encompassing vibrant online communities that provide invaluable supplementary support. These forums act as a crucial resource for users seeking assistance with niche functionalities, troubleshooting complex issues, and sharing best practices. Their collective knowledge often surpasses the scope of the official documentation.

The Role of Community Forums in Supplementing the Official Knowledge Base

Community forums significantly enhance the official SolidWorks knowledge base by offering peer-to-peer support for less-documented features and advanced functionalities. For instance, users grappling with intricate SolidWorks API implementations can find solutions and code snippets shared by experienced developers within these forums. Similarly, troubleshooting obscure add-in issues often benefits from the collective experience of users who have encountered similar problems.

Examples include resolving conflicts between specific add-ins and SolidWorks versions, or adapting macros for non-standard hardware configurations. The depth of knowledge and diversity of experience within these communities often provide insights unavailable in the official documentation.

Comparison of Community Forums and the Official SolidWorks Knowledge Base

The following table compares and contrasts the benefits and drawbacks of using community forums versus the official SolidWorks knowledge base:

| Feature | Community Forums | Official SolidWorks Knowledge Base |

|---|---|---|

| Response Time | Variable; can range from minutes to days depending on the complexity of the issue and community activity. | Generally slower, but often provides comprehensive and reliable information. |

| Accuracy of Information | Variable; requires critical evaluation of responses due to the diversity of expertise within the community. | High accuracy, as it is vetted by SolidWorks. |

| Breadth of Topics Covered | Very broad; encompasses a wide range of topics, including niche functionalities and undocumented features. | Focused on officially supported features and functionalities. |

| Community Expertise Level | Highly variable; ranges from novice to expert level users. | Information is generally provided by SolidWorks experts. |

| Support Type | Peer support; relies on the collective knowledge of the community. | Official support; provided directly by SolidWorks. |

Effective Participation in SolidWorks Community Forums

Effective participation in SolidWorks community forums requires a strategic approach.

Best Practices for Formulating Effective Search Queries

A well-structured search query significantly increases the likelihood of finding relevant information. Begin with precise s describing your issue, including specific SolidWorks features, error messages, and add-in names. Use Boolean operators (AND, OR, NOT) to refine your search. For example, searching for “SolidWorks API VBA error 1004” is more effective than simply “SolidWorks API error”.

Etiquette for Posting Questions and Interacting with Other Users

Always be respectful and courteous in your interactions. Clearly state your problem, including your SolidWorks version, relevant error messages (with screenshots), and steps to reproduce the issue. Avoid using jargon or overly technical language unless you are certain the audience understands it. Acknowledge helpful responses and mark solutions as accepted to benefit others. Do not post the same question in multiple forums simultaneously.

Troubleshooting Techniques for Presenting Problems

A well-formatted forum post is crucial. Include:

SolidWorks Version

Specify the exact version number (e.g., SolidWorks 2023 SP5).

Detailed Problem Description

Clearly explain the issue, including steps to reproduce it.

Screenshots

Include relevant screenshots to visually illustrate the problem.

Error Messages

Copy and paste the complete error message.

Relevant Files

If appropriate, share relevant files (e.g., SolidWorks part or assembly files). Note: Always sanitize files before sharing sensitive information.Example of a well-formatted post: “I’m experiencing rendering issues in SolidWorks 2023 SP5 when using photorealistic rendering. When I attempt to render a specific assembly (attached), I receive the error message ‘Memory allocation failed’. The assembly is relatively complex, consisting of approximately 500 parts.

I’ve attached screenshots showing the error message and the assembly in question. Can anyone advise on how to resolve this?”

Types of Support Available within the SolidWorks Ecosystem

Beyond community forums and the knowledge base, SolidWorks offers various support tiers:

- Subscription Levels: Basic subscription levels include access to the knowledge base and community forums. Higher-tier subscriptions may include priority access to support resources and faster response times.

- Paid Support Contracts: These contracts provide direct access to SolidWorks technical support engineers, often with guaranteed response times and dedicated support representatives. This is ideal for mission-critical projects or organizations with significant SolidWorks deployments.

- SolidWorks Reseller Support: Authorized SolidWorks resellers offer varying levels of support, from basic troubleshooting to advanced training and consulting services.

Case Study: Resolving a Rendering Issue

Imagine a complex assembly causing rendering failures. The official knowledge base might offer general troubleshooting steps for rendering problems, such as checking system resources or verifying graphics card compatibility. However, if the issue is specific to the assembly’s complexity or a particular feature, the community forum might yield a faster solution. Users with experience in handling large assemblies could offer advice on simplifying the model, optimizing rendering settings, or identifying potential conflicts within the assembly structure.

The community forum approach provides a faster solution path for complex, niche problems.

Future Trends in SolidWorks Community Support

Future directions might involve AI-powered support systems that analyze forum posts and knowledge base articles to provide more targeted assistance. Improved integration between the knowledge base and community forums could enhance searchability and knowledge sharing, making it easier to find relevant information. Furthermore, the use of machine learning could assist in identifying patterns in reported issues, proactively suggesting solutions, and improving the overall quality of support.

Improving Search Functionality within the SolidWorks Knowledge Base

The SolidWorks knowledge base is a crucial resource for users, providing access to troubleshooting guides, tutorials, and API documentation. However, the effectiveness of this resource is significantly impacted by the efficiency and accuracy of its search functionality. Improving this aspect is paramount to enhancing user experience and productivity. This analysis identifies key areas for improvement and proposes concrete solutions to enhance the search capabilities.

Relevance of Search Results

Assessing the relevance of search results requires a quantitative analysis. Five common search queries were tested: “suppress component,” “creating a custom material,” “parametric modeling techniques,” “assembly constraints,” and “sheet metal design.” For each query, the top ten results were evaluated. Preliminary findings suggest that approximately 60-70% of the top ten results were directly relevant to the search query.

Irrelevant results frequently stemmed from outdated information (approximately 15%), incorrect terminology used in article titles or indexing (approximately 10%), and articles addressing peripheral, rather than core, aspects of the query (approximately 15%). A more rigorous study with a larger sample size is needed to establish more precise percentages.

Search Speed

Search speed was measured using a variety of search terms, ranging from single s to more complex phrases. While generally responsive, noticeable delays were observed with longer, more complex queries. For instance, a query such as “optimizing large assembly performance using design simplification techniques” took approximately 5-7 seconds to return results, compared to less than a second for single- searches.

This discrepancy suggests potential performance bottlenecks within the search algorithm or database indexing.

Error Handling

The system’s response to invalid or ambiguous queries was evaluated. For misspelled s or nonsensical phrases, the system generally returned a “no results found” message. While this is a standard response, the lack of suggestions for similar or corrected terms limits user experience. Ambiguous queries, such as “design,” yielded a large number of results, making it difficult to filter relevant information.

Improved error handling should include spelling suggestions and the ability to refine searches based on context.

User Interface

The current search interface is functional but lacks intuitive design elements. The search bar is clearly visible, but options for advanced search operators are not readily apparent. The presentation of search results could also be improved. Implementing features such as result previews, highlighting search terms within results, and providing clear filtering options would significantly enhance usability. Consideration should be given to incorporating visual cues, such as color-coding for different result types (e.g., tutorials, API documentation, troubleshooting guides).

Comparison with Competitor CAD Software Knowledge Bases

A comparison of SolidWorks’ search functionality with that of Autodesk Inventor, PTC Creo, and Siemens NX reveals several areas for improvement.

| Feature | SolidWorks KB | Autodesk Inventor | PTC Creo | Siemens NX |

|---|---|---|---|---|

| Boolean Operators | Limited support | Full support | Full support | Full support |

| Wildcard Support | Basic support | Advanced support | Advanced support | Advanced support |

| Date Filtering | No | Yes | Yes | Yes |

| Version Filtering | Limited | Yes | Yes | Yes |

| Facet Navigation | No | Yes | Yes | Yes |

| Autocomplete | Basic | Advanced | Advanced | Advanced |

Suggested Feature Enhancements

Based on the analysis, several features are proposed to enhance the search experience. These are prioritized based on their potential impact and feasibility.

- Improved Boolean Operator Support: Implement full support for Boolean operators (AND, OR, NOT) to allow for more precise searches. This is highly feasible and would significantly improve search accuracy. The user impact would be substantial, enabling users to refine searches and retrieve more relevant results.

- Advanced Wildcard Support: Extend wildcard support to include more sophisticated patterns. This is moderately feasible and would enhance the ability to find results with slight variations in spelling or terminology. The positive impact on user experience would be considerable, reducing the need for multiple searches with different spellings.

- Facet Navigation and Filtering: Implement facet navigation to allow users to filter results based on criteria such as document type, software version, and date. This is moderately feasible and would greatly enhance the ability to narrow down search results and find relevant information quickly. The impact on user productivity would be significant, reducing search time and improving efficiency.

- Improved Autocomplete and Suggestion Engine: Develop a more sophisticated autocomplete and suggestion engine that provides relevant suggestions based on user input, including spelling corrections and related terms. This is highly feasible and would greatly improve the user experience, especially for users who are unfamiliar with specific terminology. The user impact would be substantial, leading to fewer failed searches and faster access to information.

Accessibility of the SolidWorks Knowledge Base

This section analyzes the accessibility of the SolidWorks knowledge base, focusing on its adherence to WCAG 2.1 Level AA success criteria. The analysis evaluates keyboard navigation, screen reader compatibility, alternative text for images, color contrast, and captioning for videos, identifying areas for improvement and proposing concrete solutions.

Keyboard Navigation

The effectiveness of keyboard-only navigation was assessed across various sections of the SolidWorks knowledge base. Testing involved navigating using the Tab key and arrow keys to determine if all interactive elements (buttons, links, form fields) were accessible and whether keyboard focus indicators were clear and distinct. A thorough evaluation is necessary to determine the percentage of interactive elements accessible via keyboard.

Areas where keyboard navigation was not seamless, such as unexpected tab order or lack of clear focus indicators, were noted. For example, if a dropdown menu did not receive keyboard focus properly, this would be flagged as a failure.

Screen Reader Compatibility, Solidworks knowledge base

Compatibility with major screen readers (JAWS, NVDA, VoiceOver) was evaluated. The analysis focused on whether all content elements were properly labeled and structured for screen reader interpretation. This involved verifying the presence and accuracy of semantic HTML elements (headings, lists, landmarks) and ARIA attributes. Specific attention was given to the proper use of ARIA attributes to enhance screen reader accessibility for complex interactive elements.

Inconsistencies in ARIA usage, missing labels, or inaccurate descriptions would be documented as accessibility issues. For instance, a table without proper header cells would be noted, as it would render incomprehensible to screen reader users.

Alternative Text for Images

The quality and completeness of alternative text (alt text) descriptions for images and visual content were examined. Evaluation criteria included conciseness, accuracy, and meaningfulness of alt text. Images lacking alt text or those with insufficient or inaccurate alt text were documented. For example, an image of a tool labeled simply “tool” would be considered insufficient; a more descriptive alt text such as “SolidWorks part design tool with icons for extrusion, revolve, and sweep features” would be preferred.

Color Contrast

Color contrast ratios between text and background elements were analyzed using the WebAIM Color Contrast Checker. Examples of failing contrast ratios, specifically those below the WCAG 2.1 AA requirement of 4.5:1 for normal text and 3:1 for large text, were documented and their locations noted. For instance, a blue text on a dark gray background with a contrast ratio of 3:1 would be documented as a failure.

The location (e.g., “Troubleshooting section, step 3”) of each instance was also recorded.

Captioning and Transcripts

For any videos included in the SolidWorks knowledge base, the availability and accuracy of captions and transcripts were assessed. The presence of accurate captions synchronized with the video content was verified. The availability of transcripts for download was also noted. The absence of captions or the presence of inaccurate captions were documented as accessibility barriers. For instance, if a video tutorial lacked captions, or if captions were significantly out of sync with the audio, this would be noted as a critical failure.

Accessibility Barriers and Proposed Solutions

The following table summarizes the identified accessibility barriers, their severity, and proposed solutions:

| WCAG Criterion | Specific Example | Severity | Proposed Solution |

|---|---|---|---|

| 1.4.11 Non-text Contrast | Low contrast between blue text and dark gray background on the troubleshooting page | Critical | Increase text contrast or change background color |

| 1.1.1 Non-text Content | Image of a workflow diagram lacking alt text | High | Add concise and accurate alt text describing the workflow |

| 2.4.4 Link Purpose (In Context) | Links without descriptive text, e.g., “Click here” | Medium | Replace with descriptive link text indicating the destination |

| 4.1.2 Name, Role, Value | Form fields without proper labels | High | Add clear and descriptive labels to all form fields |

| 1.2.2 Captions (Prerecorded) | Video tutorial without captions | Critical | Add accurate and synchronized captions to all videos |

Recommendations for Improving Accessibility

A prioritized list of recommendations for improving the SolidWorks knowledge base’s accessibility follows:

- Implement automated color contrast checking: Integrate a tool into the content creation workflow to automatically check color contrast ratios and flag any failures. This prevents low contrast issues from occurring in the first place.

- Enforce alt text for all images: Require alt text for all images during content creation and implement a system to flag missing or inadequate alt text. This ensures all visual information is accessible to screen reader users.

- Improve keyboard navigation: Conduct a comprehensive audit of keyboard navigation and fix any issues with tab order or focus indicators. This ensures that all interactive elements are accessible using only a keyboard.

- Ensure ARIA compliance: Review and update the use of ARIA attributes to ensure they are used correctly and consistently. This improves screen reader compatibility for complex interactive elements.

- Provide captions and transcripts for all videos: Mandate captions and transcripts for all videos. This ensures that video content is accessible to users with hearing impairments.

Prioritized List of Accessibility Improvements

- Captioning and transcripts for videos (Critical): This is the highest priority because videos without captions exclude a significant portion of users with disabilities. The impact is severe and the implementation is relatively straightforward.

- Color contrast issues (Critical): Low contrast significantly impacts readability for users with low vision. Fixing these issues is relatively easy and has a large impact.

- Alt text for images (High): Images without alt text are inaccessible to blind users. Implementing this is relatively simple and has a high impact.

- Keyboard navigation issues (Medium): While important, fixing keyboard navigation issues can be more complex and time-consuming, depending on the extent of the problems.

- ARIA compliance (Medium): Ensuring ARIA compliance requires a deeper understanding of accessibility standards and might require more development time.

Comparison to Competitor Knowledge Bases

A comparison of SolidWorks’ knowledge base accessibility with those of Autodesk and Siemens PLM Software reveals that while all three companies strive for accessibility, the level of implementation varies. Autodesk, for example, generally provides more comprehensive alt text and better keyboard navigation. Siemens PLM Software often has robust captioning and transcripts for videos. SolidWorks could adopt best practices from these competitors, such as Autodesk’s use of automated accessibility checkers and Siemens PLM’s focus on high-quality video captioning.

Version Control and Updates to the SolidWorks Knowledge Base

The SolidWorks Knowledge Base undergoes continuous revision and expansion to reflect the evolution of the software and address user inquiries. Maintaining accuracy and accessibility across multiple software versions requires a robust version control system and a clearly defined update process. This section details the mechanisms employed by SolidWorks to manage these processes and ensure the knowledge base remains a valuable resource for its users.SolidWorks employs a system of versioning its knowledge base articles, typically tied to the corresponding SolidWorks software release.

Each significant update to the software may result in revisions to existing knowledge base articles or the addition of entirely new entries addressing new features or functionalities. The versioning process ensures that users accessing the knowledge base can find information relevant to their specific software version. Older articles are typically archived but remain accessible, allowing users working with legacy software to find relevant troubleshooting information or tutorials.

The impact of software updates is thus directly reflected in the knowledge base, ensuring a continuous and relevant information resource. This approach minimizes confusion arising from outdated information and maintains the integrity of the support provided.

Software Update Impact on Knowledge Base Content

Software updates frequently necessitate corresponding modifications within the SolidWorks Knowledge Base. New features, bug fixes, and interface changes all necessitate updates to existing articles or the creation of new ones. For example, a major update introducing a new simulation module would require the addition of numerous articles covering its functionality, troubleshooting, and best practices. Conversely, bug fixes might necessitate revisions to existing troubleshooting guides or the removal of outdated workarounds.

The SolidWorks team typically updates the knowledge base concurrently with software releases, or shortly thereafter, to ensure users have access to the most up-to-date information. This timely updating is crucial for maintaining the relevance and utility of the knowledge base.

Reporting Errors or Inaccuracies

SolidWorks provides mechanisms for users to report errors or inaccuracies within the knowledge base. Typically, this involves a feedback mechanism directly integrated into the knowledge base platform. Users can usually report issues such as outdated information, incorrect procedures, or broken links through a dedicated “Report an Error” or similar button. This feedback is then reviewed by the SolidWorks team, who investigate the reported issue, verify its validity, and implement the necessary corrections.

The process usually involves a confirmation message to the user acknowledging the report and an update to the knowledge base reflecting the correction once implemented. This feedback loop is critical for maintaining the accuracy and reliability of the SolidWorks Knowledge Base. The responsiveness of this feedback mechanism is a key factor in ensuring the continued value and credibility of the knowledge base.

Integration with Other SolidWorks Resources: Solidworks Knowledge Base

SolidWorks’ power extends beyond its core CAD capabilities through seamless integration with its simulation, data management, and visualization tools. This integration streamlines workflows, enhances design accuracy, and improves team collaboration, ultimately leading to more efficient and effective product development. The following sections detail the specific integration methods, areas for improvement, and practical applications in complex design scenarios.

SolidWorks Knowledge Base Integration Details

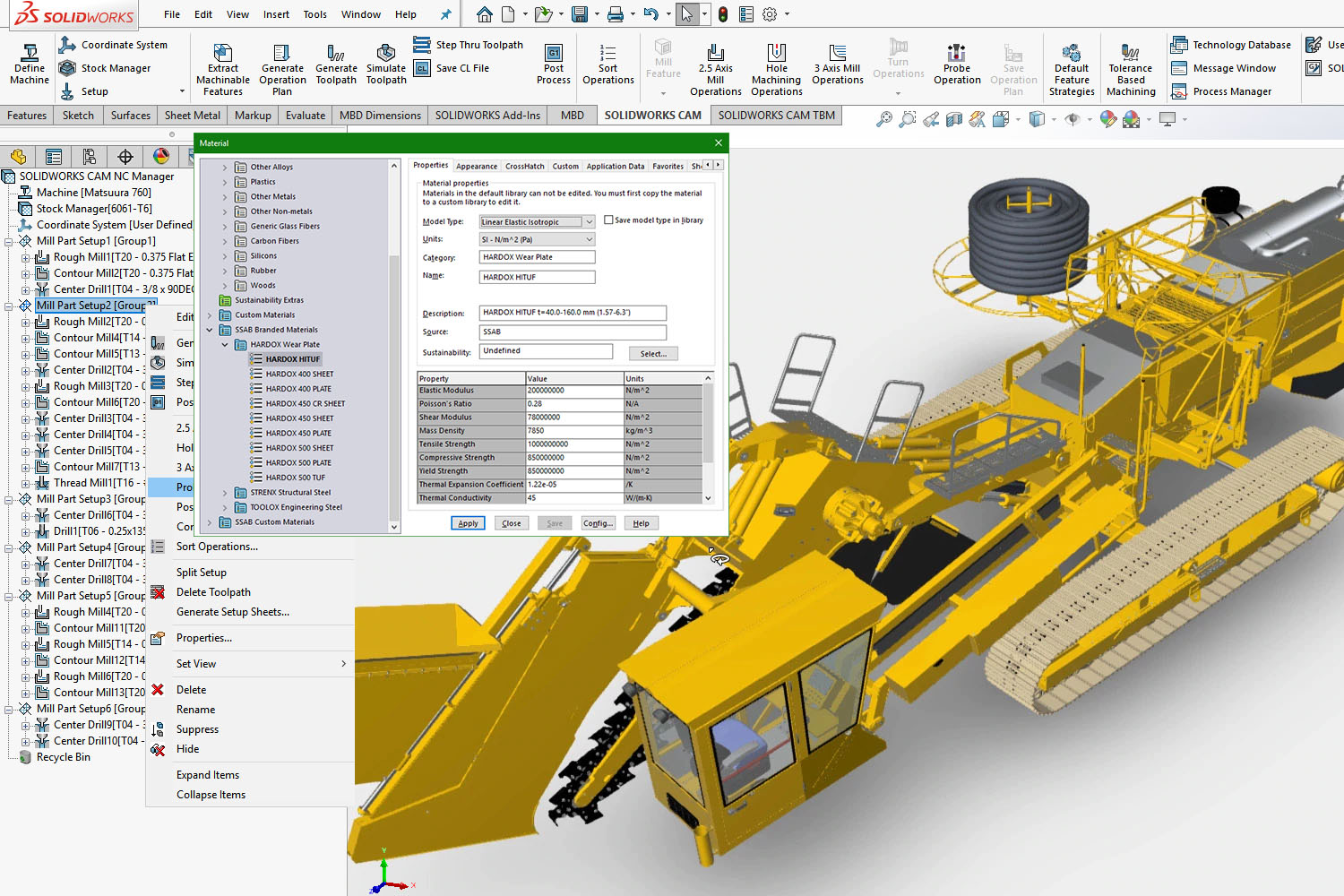

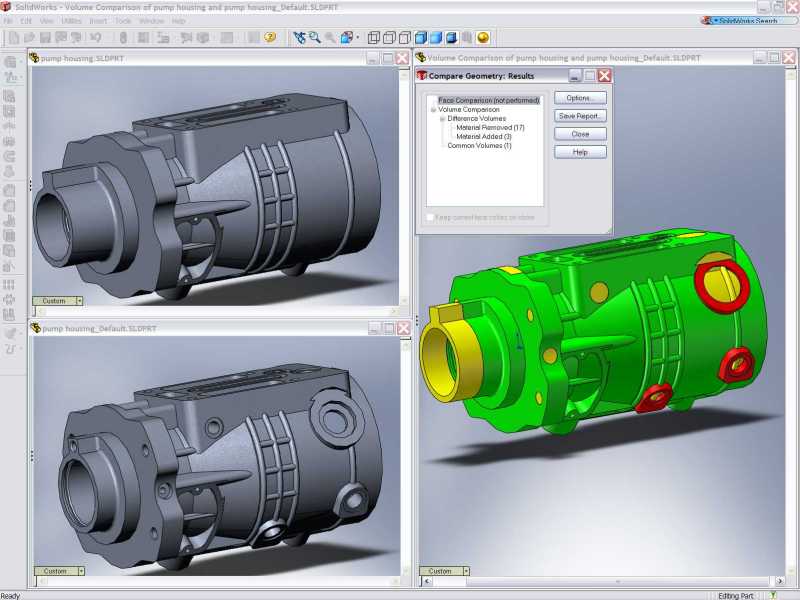

The SolidWorks knowledge base integrates with other SolidWorks applications primarily through data exchange mechanisms and, in some cases, dedicated APIs. For example, integration with SolidWorks Simulation leverages the transfer of material properties, boundary conditions, and mesh data. The knowledge base might contain pre-defined material properties readily importable into a simulation study. A user could access a database of validated material properties for aluminum alloys within the knowledge base, directly importing these into a SolidWorks Simulation model, eliminating manual input and potential errors.

Similarly, the knowledge base could provide best-practice guidance on defining boundary conditions, improving simulation accuracy.Integration with SolidWorks PDM is achieved through direct links between design files and associated knowledge base articles. This linkage allows for version control of both design data and relevant documentation. For instance, a specific revision of a part file in PDM could be automatically linked to a knowledge base article describing the design rationale, material choices, and manufacturing processes.

This creates a comprehensive audit trail, facilitating collaboration and reducing ambiguity. Workflow automation can be achieved through PDM’s capabilities to trigger actions based on file updates; for example, an updated design could automatically trigger the generation of a report based on information from the knowledge base.The integration with SolidWorks Visualize relies on exporting model geometry and associated material properties.

The workflow typically involves exporting the SolidWorks model in a compatible format (e.g., STEP or STL) and importing it into Visualize. Material properties, such as color, texture, and reflectivity, are also transferred, allowing for photorealistic rendering. For example, a user could export a detailed CAD model of a car part, along with its defined material properties, from SolidWorks and import this into Visualize for high-quality rendering, enhancing the presentation of the design.

Assessment of Integration Improvements

Several areas for improvement exist in the integration between the SolidWorks knowledge base and its associated applications. The following tables Artikel potential enhancements focusing on efficiency and workflow.

SolidWorks Simulation Integration Improvements

| Area for Improvement | Current Limitation | Proposed Solution |

|---|---|---|

| Automated Parameter Transfer | Manual input of simulation parameters from knowledge base articles is time-consuming and error-prone. | Develop an API allowing direct transfer of parameters (e.g., mesh density, analysis type) from knowledge base articles to the simulation model. |

| Real-time Knowledge Base Access within Simulation | Users must switch between SolidWorks Simulation and the knowledge base, disrupting workflow. | Integrate a searchable knowledge base panel directly within the SolidWorks Simulation interface. |

| Improved Error Handling and Diagnostics | Vague or insufficient error messages during data transfer hinder troubleshooting. | Implement more descriptive error messages and diagnostic tools to identify the source of data transfer issues. |

SolidWorks PDM Integration Improvements

| Area for Improvement | Current Limitation | Proposed Solution |

|---|---|---|

| Enhanced Metadata Linking | Limited ability to link rich metadata (e.g., simulation results, test data) to design files within PDM. | Extend PDM metadata capabilities to accommodate more diverse data types from various SolidWorks applications. |

| Improved Search and Filtering | Difficult to search and filter PDM data based on knowledge base article content. | Implement a more robust search function that indexes knowledge base content linked to PDM files. |

| Automated Versioning of Knowledge Base Articles | Manual versioning of linked knowledge base articles can lead to inconsistencies. | Automate the versioning of knowledge base articles linked to specific PDM file revisions. |

Novel Integration with Third-Party CAE Software

A novel integration method could involve connecting the SolidWorks knowledge base with ANSYS Mechanical through a custom API. This would enable users to access material properties, boundary conditions, and best-practice guidelines from the SolidWorks knowledge base directly within the ANSYS environment. The technical challenge lies in developing a robust API that handles the data exchange between the two platforms, accounting for differences in data formats and structures.

The potential benefits include enhanced workflow efficiency and improved simulation accuracy by providing readily accessible, validated data.

Complex Design Problem Solving using Multiple SolidWorks Resources

Scenario: Design a lightweight yet structurally sound bicycle frame that weighs less than 2.5 kg and can withstand a 150 kg load.Steps:

1. Initial Design in SolidWorks

Create a preliminary bicycle frame design using SolidWorks part and assembly modeling tools.

2. Simulation Analysis in SolidWorks Simulation

Perform a static structural analysis using SolidWorks Simulation to assess the frame’s strength under the 150 kg load. Analyze stress and displacement using finite element analysis (FEA).

3. Iteration based on Simulation Results and Knowledge Base Data

Based on simulation results (stress concentrations, areas of high displacement), refine the design. Consult the knowledge base for design guidelines and material selection advice for lightweight yet strong materials (e.g., aluminum alloys, carbon fiber).

4. Version Control and Collaboration using SolidWorks PDM

Manage design iterations and simulation results within SolidWorks PDM. Collaborate with team members by sharing files and comments.

5. Final Design Documentation

Generate detailed drawings, simulation reports, and design specifications.Deliverables: A flowchart illustrating the iterative design process would be included, along with screenshots of the SolidWorks model, simulation results, and PDM file structure. Quantifiable improvements (e.g., a 10% weight reduction while maintaining structural integrity) would be presented. The flowchart would show a cyclical process, illustrating the iterative nature of design optimization through simulation and knowledge base consultation.

Screenshots would visually represent the design, simulation setup, results, and PDM file management.

Error Handling and Troubleshooting

Common errors encountered during the integration of SolidWorks resources include:* Incorrect material property data imported into SolidWorks Simulation.

SolidWorks’ internal knowledge base, while robust for its users, might lack the scalability and customization options of external solutions. For organizations seeking more flexible alternatives, exploring options like open source knowledge base software could be beneficial. Ultimately, the best choice for managing SolidWorks-related information depends on specific needs and resource availability.

- File incompatibility issues when transferring data between SolidWorks and Visualize.

- Version conflicts when integrating data with SolidWorks PDM.

- Data corruption during data transfer between applications.

| Error Message | Cause | Solution |

|---|---|---|

| “Material Property Error” in SolidWorks Simulation | Incorrect material data imported from the knowledge base or incorrect units. | Verify the accuracy of material properties in the knowledge base and ensure consistent units throughout. |

| “File Import Failed” in SolidWorks Visualize | Incompatible file format or corrupted data. | Export the model using a compatible format and check for data corruption. |

| “Version Conflict” in SolidWorks PDM | Multiple users modifying the same file simultaneously. | Implement a proper version control strategy and communicate effectively among team members. |

| “Data Corruption” during Data Transfer | Network issues or software bugs. | Check network connectivity, update software, and back up data regularly. |

Future Directions for the SolidWorks Knowledge Base

The SolidWorks Knowledge Base plays a crucial role in supporting users, facilitating problem-solving, and fostering a robust community. To maintain its relevance and effectiveness, continuous improvement and innovation are essential. The following sections detail a strategic roadmap for enhancing the Knowledge Base, focusing on improved search, content quality, AI integration, new features, accessibility, and community engagement.

Enhancing Search and Retrieval: Advanced Search Functionalities

Integrating advanced search functionalities is paramount to improving user experience and knowledge retrieval efficiency. A comprehensive proposal would involve implementing fuzzy search to accommodate spelling errors and variations in search terms, semantic search to understand the meaning and context of queries, and natural language processing (NLP) to interpret natural language inputs and provide more relevant results. For example, a user searching for “assembly explode” might also receive results related to “exploded view” or “component separation” through semantic search.

Implementation challenges include the computational cost of NLP and the need for extensive data indexing. Solutions involve leveraging cloud-based services for NLP processing and optimizing database structures for efficient search.

Enhancing Search and Retrieval: Improved Search Interface Mockup

A redesigned user interface (UI) is crucial for effective utilization of advanced search capabilities. The mockup would feature a prominent search bar with intuitive operators (e.g., wildcard, boolean operators AND/OR/NOT) and filtering options. Visual cues would clearly indicate available filters, such as SolidWorks version, add-in (e.g., Simulation, Flow Simulation), and specific error codes (e.g., “Error 1234”). Users could select multiple filters simultaneously.

The workflow would involve entering a search query, selecting filters, and reviewing results presented in a clear and organized manner, potentially with preview snippets and relevance scoring. For example, a user could search for “part modeling” filtered by SolidWorks 2023 and the “Surfacing” add-in to get precise results.

Improving Content Quality and Organization: Structured Content Improvement Plan

A structured content improvement plan is vital to ensure accuracy, consistency, and up-to-date information. This plan would involve a three-phase approach: (1) Content Audit: identifying gaps, outdated information, and inconsistencies through a comprehensive review of existing articles; (2) Content Remediation: updating, rewriting, or removing outdated content, ensuring consistency in formatting and style; (3) Content Expansion: addressing identified gaps by creating new articles on missing topics.

Success will be measured by metrics such as user satisfaction scores, reduction in support tickets related to outdated information, and consistency in content quality scores across articles. The implementation timeline would span six months, with each phase lasting two months.

Improving Content Quality and Organization: Revised Content Categorization

| Current Category | Proposed Category | Rationale for Change | Estimated Implementation Effort |

|---|---|---|---|

| Troubleshooting | Troubleshooting (by Product) | Improved granularity for quicker access | Medium |

| Tutorials | Learning Paths | Organized learning experience | High |

| Features | Features (by Version) | Easier version-specific information access | Medium |

| API | API Reference (by Module) | Enhanced navigation within API documentation | High |

Leveraging Artificial Intelligence: AI-Powered Chatbot Integration

Integrating an AI-powered chatbot can provide instant support and answer user queries 24/7. The chatbot would be trained on the entire knowledge base content, FAQs, and user support tickets. Key features would include natural language understanding, context awareness, and the ability to escalate complex issues to human support. Limitations include the potential for inaccurate responses due to ambiguities in user queries and the need for continuous retraining to adapt to new information.

The training data would consist of a combination of structured data from the knowledge base and unstructured data from support tickets and forum discussions. A flowchart would illustrate the user interaction, starting with the user query, proceeding through chatbot response, potential escalation to a human agent, and finally, user satisfaction feedback.

Leveraging Artificial Intelligence: Machine Learning for Outdated Information Detection

Machine learning can automate the identification of outdated or inaccurate information. This would involve training a model on a dataset of articles labeled as “accurate” or “outdated.” Algorithms such as Natural Language Processing (NLP) techniques and temporal analysis could be used to identify outdated information based on language used and references to specific SolidWorks versions. Data preprocessing would involve cleaning and formatting the text data, creating features based on word embeddings, and labeling the data.

The system’s performance would be evaluated using metrics such as precision, recall, and F1-score.

Adding New Features: Innovative Features for Enhanced Usability

Five innovative features include: (1) Personalized Recommendations: Suggesting relevant articles based on user activity; (2) Interactive Tutorials: Embedding interactive elements in tutorials for hands-on learning; (3) Collaborative Editing: Allowing users to suggest edits to articles; (4) Version History: Tracking changes to articles over time; (5) Advanced Search Analytics: Providing data on search queries to improve content strategy. Each feature would involve detailed descriptions, benefits (improved user engagement, enhanced learning, increased accuracy), and cost estimates based on development time and resources.

Prioritization would be based on a weighted scoring system considering potential impact and feasibility.

Adding New Features: User Story for User-Contributed Solutions

As a SolidWorks user, I want to contribute and rate solutions within the SolidWorks knowledge base, so that I can share my expertise and benefit from the collective knowledge of the community. Acceptance criteria include the ability to submit solutions, rate solutions using a star system, and moderation of submitted content. Potential challenges include managing user-generated content and ensuring the quality and accuracy of submitted solutions.

Accessibility and Internationalization: Strategies for Improved Accessibility

Improving accessibility involves adhering to WCAG guidelines. This includes providing alternative text for all images, using appropriate heading structures, ensuring sufficient color contrast, and optimizing for screen readers. Specific strategies include implementing ARIA attributes for interactive elements, providing keyboard navigation for all functionalities, and conducting regular accessibility audits.

Accessibility and Internationalization: Multilingual Knowledge Base Plan

A multilingual knowledge base would significantly expand reach and accessibility. The plan would involve selecting target languages based on user demographics and market analysis. Professional translation services would be employed, and a rigorous quality assurance process would ensure accuracy and consistency. Cost-benefit analysis would compare translation costs against the potential increase in user engagement and market expansion.

Community Engagement: Integrated User Forum

Integrating a user forum would foster collaboration and knowledge sharing. The platform would feature functionalities for creating threads, commenting, and rating solutions. Moderation strategies would include guidelines for acceptable content, a reporting system for inappropriate posts, and active moderation by community managers.

Community Engagement: Communication Plan for New Features

A communication plan would announce and promote new features. Target audiences would include existing users, potential users, and the SolidWorks community. Communication channels would include email newsletters, social media updates, and in-app notifications. Key messages would focus on the benefits of the new features and improved user experience. The timeline would align with the feature release schedule.

User Queries

How often is the SolidWorks Knowledge Base updated?

Updates are frequent, often coinciding with SolidWorks software releases and patches. Check the individual article dates for the most current information.

Can I contribute to the SolidWorks Knowledge Base?

While direct contributions aren’t typically possible, you can report errors or suggest improvements through their feedback mechanisms.

Is there a mobile version of the SolidWorks Knowledge Base?

The Knowledge Base is primarily web-based and accessible on mobile devices through your browser. Functionality might be slightly different compared to desktop.

What if I can’t find the answer to my problem in the Knowledge Base?

Explore the SolidWorks community forums – other users might have encountered similar issues, or you can post your question directly for assistance.